Maintenance Management

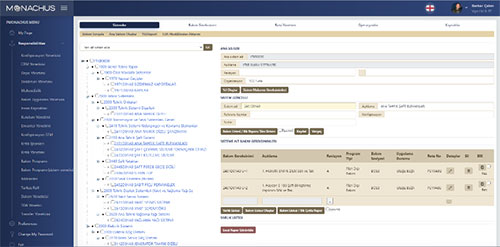

Maintenance Program

It is the module where routine work methods are defined and matched with assets. Depending on which counter and how often the routine work method defined for the matched asset will be applied is determined.

Work methods can be grouped and assigned to assets, and planning is done accurately on a defined group basis.

Consumables, spare parts, personnel and other resource needs required for the routine work method are entered on an amount or hour basis.

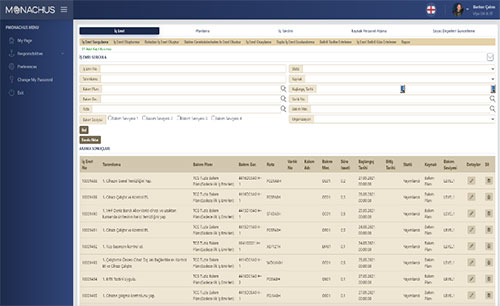

Maintenance Implementation

It is the module where planned maintenance is converted into work orders by the system within the framework of the definitions in the Maintenance Program Module and work orders can be created by work units for non-standard works.

With the planning tool, work orders are automatically prepared within the specified date range for all assets defined in the system.

The work unit can turn a defined work method into a work order and assign personnel. Planned, completed and canceled work orders can be monitored on a weekly, monthly and annual basis.